Markets are becoming increasingly competitive and to be part of them, companies need to become more efficient or they will not survive long.

Manufacturing companies should aim to save time, costs and resources in order to compete. Therefore, they need to pursue perfection and adopt a good methodology.

Today we will look at how Odoo features can help you implement Lean Manufacturing. But first we need to know what this philosophy is about.

What is Lean Manufacturing?

Lean Manufacturing is a methodology which companies in the West started implementing in the 80s and today entities use it more and more in the modern business world.

Lean means "Produce exactly what the client wants, when he wants, at a fair price and with minimum waste". To achieve that goal, you need a wide range of tools and techniques such as Gemba Walks, Andon Systems, standardized work or TPM.

Luckily, Odoo can assist with much of this process in almost any industry.

What is Odoo

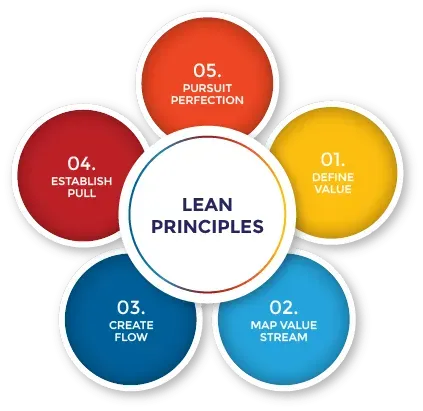

Lean Manufacturing: 5 Principles and How Odoo Features Support Them

This approach focuses on optimizing resources to gain competitive advantage and prohibits the use of resources for purposes other than creating value for the customer. For a correct adoption of Lean, it is important to follow the 5 principles, and Odoo features are helpful to achieve this.

Define Value

Product management: Odoo allows you to manage products, track their attributes and define customer-focused descriptions. This helps you to tailor your offerings to your customers' needs.

Map Value Stream

Inventory Management: Odoo's Inventory Management module helps you track the movement of goods through the supply chain. It assists in identifying the value stream from suppliers to customers.

Inventory Management Software

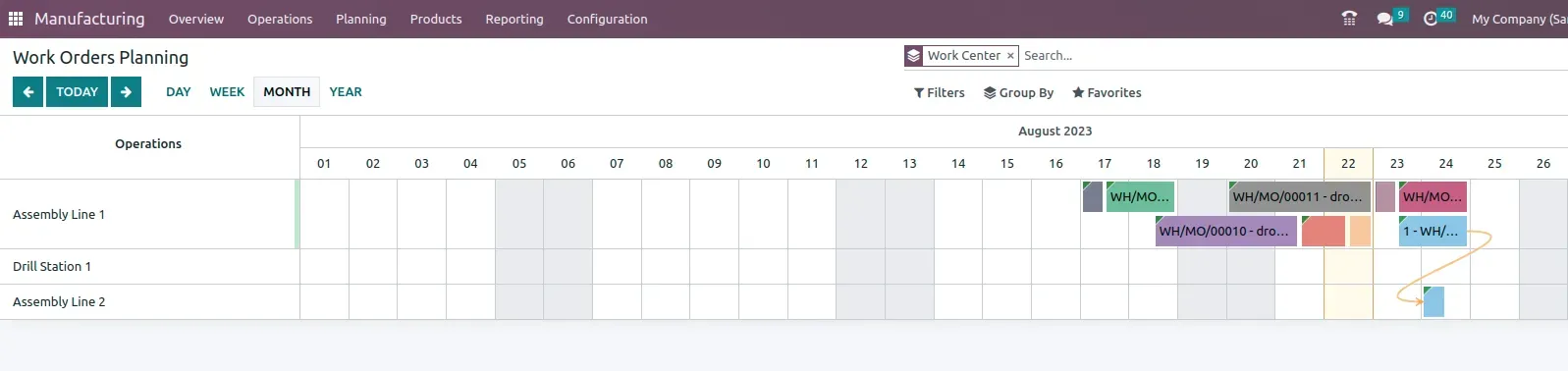

Production Planning: You can organize and plan production tasks with Odoo's manufacturing module, ensuring effective value stream management.

Production Planning with Odoo

Make the Value Flow Through the Value Stream

Workflow Automation: With Odoo, you can automate various processes. You'll see how it minimizes bottlenecks and guarantees a more seamless flow of information and work throughout the organization.

Pull the Value from the Value Stream

Sales and Purchase Orders: Odoo's sales and purchase order management features allow you to create orders based on actual demand. The functionality pulls value through the value stream based on customer orders.

Strive for Perfection

Continuous Improvement: Odoo's reporting and analytics tools help you monitor key performance indicators (KPIs) and identify areas for improvement. This aligns with the Lean principle of striving for perfection.

Lean Manufacturing: 8 Types of Waste

According to this methodology, 8 major categories of waste have been defined. Activities belonging to one of these categories must, at best, be eliminated or, otherwise, reduced to a minimum.

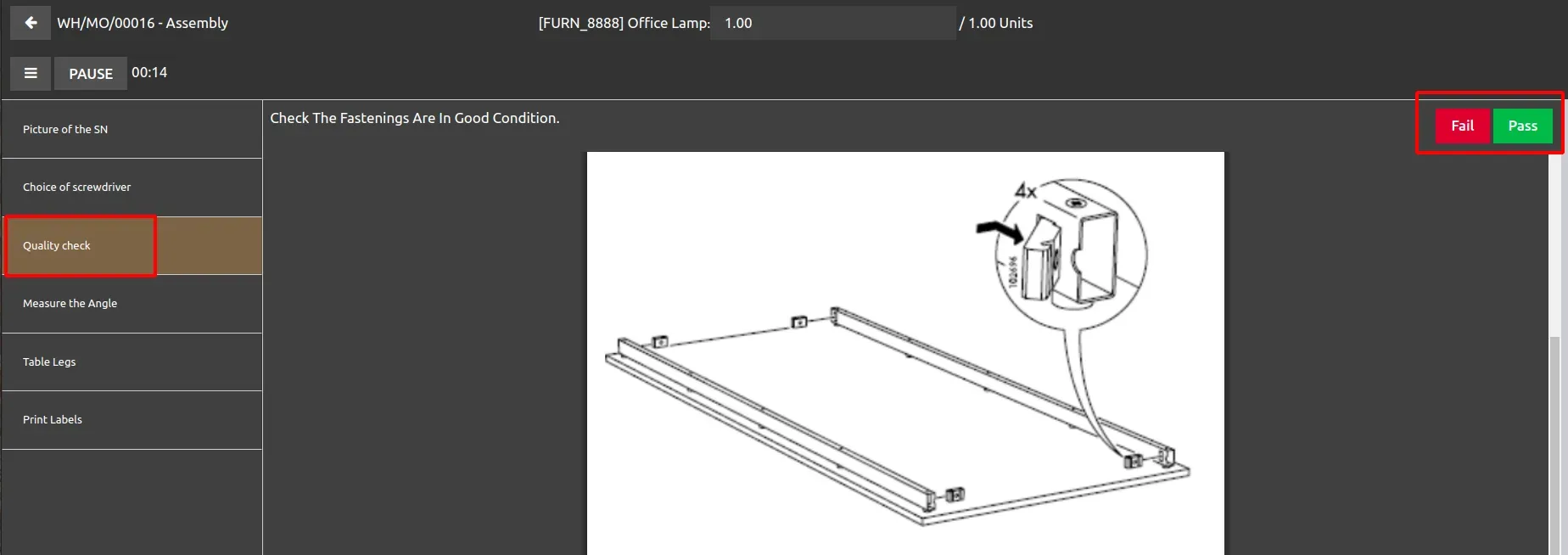

Defects

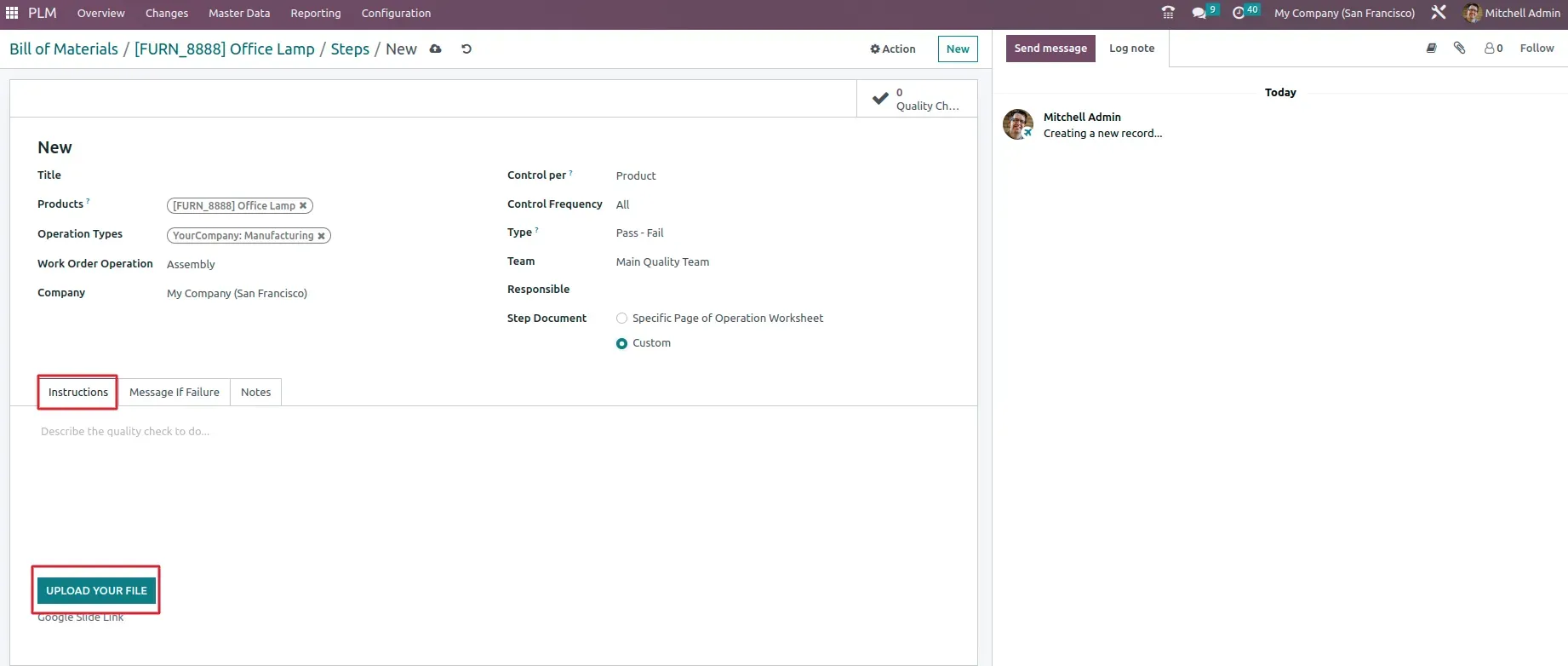

Quality Control: Odoo's quality control features enable you to define quality checks at various stages of production. You can ensure that products meet specified standards, reducing the risk of defects.

Quality Management with Odoo

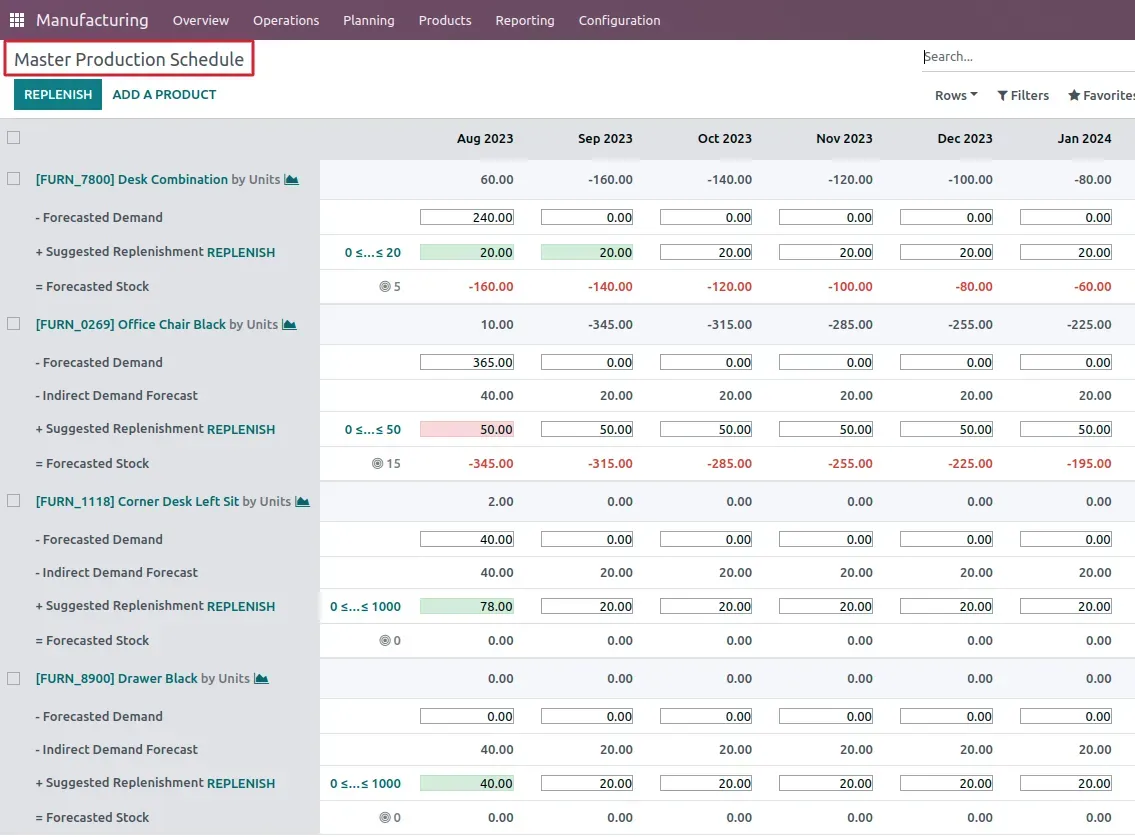

Overproduction

Demand Forecasting: Odoo's reporting and analytics capabilities can help you forecast demand more accurately. It allows you to produce goods based on actual demand and avoid excessive production.

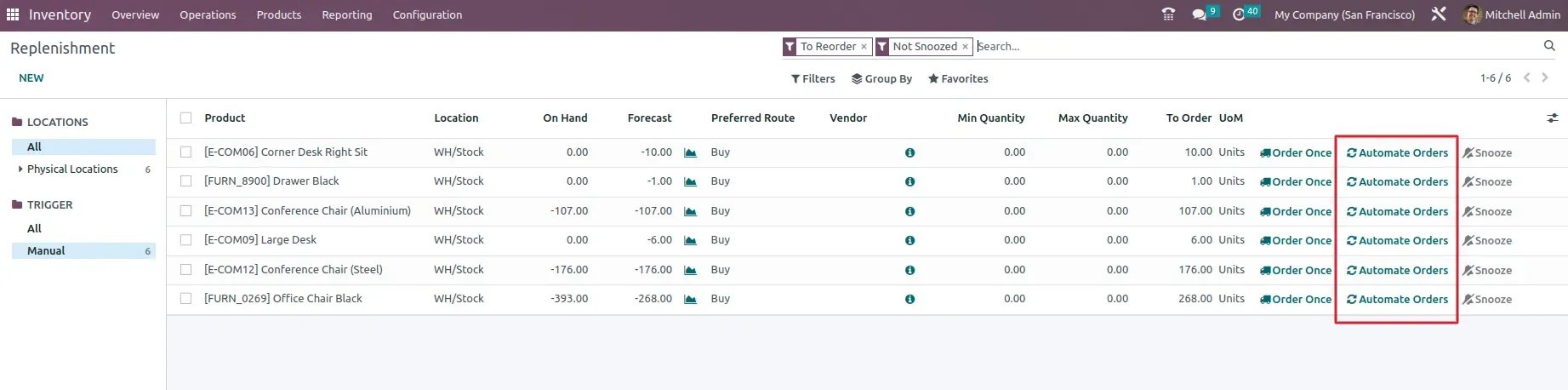

Inventory Replenishment Strategies

Waiting

Workflow Automation: By automating processes such as approvals and notifications, Odoo minimizes waiting times and ensures tasks move smoothly through the workflow. With direct messaging (similar to Slack) and topics, email integration and project management.

Integrated Business Operations with Odoo

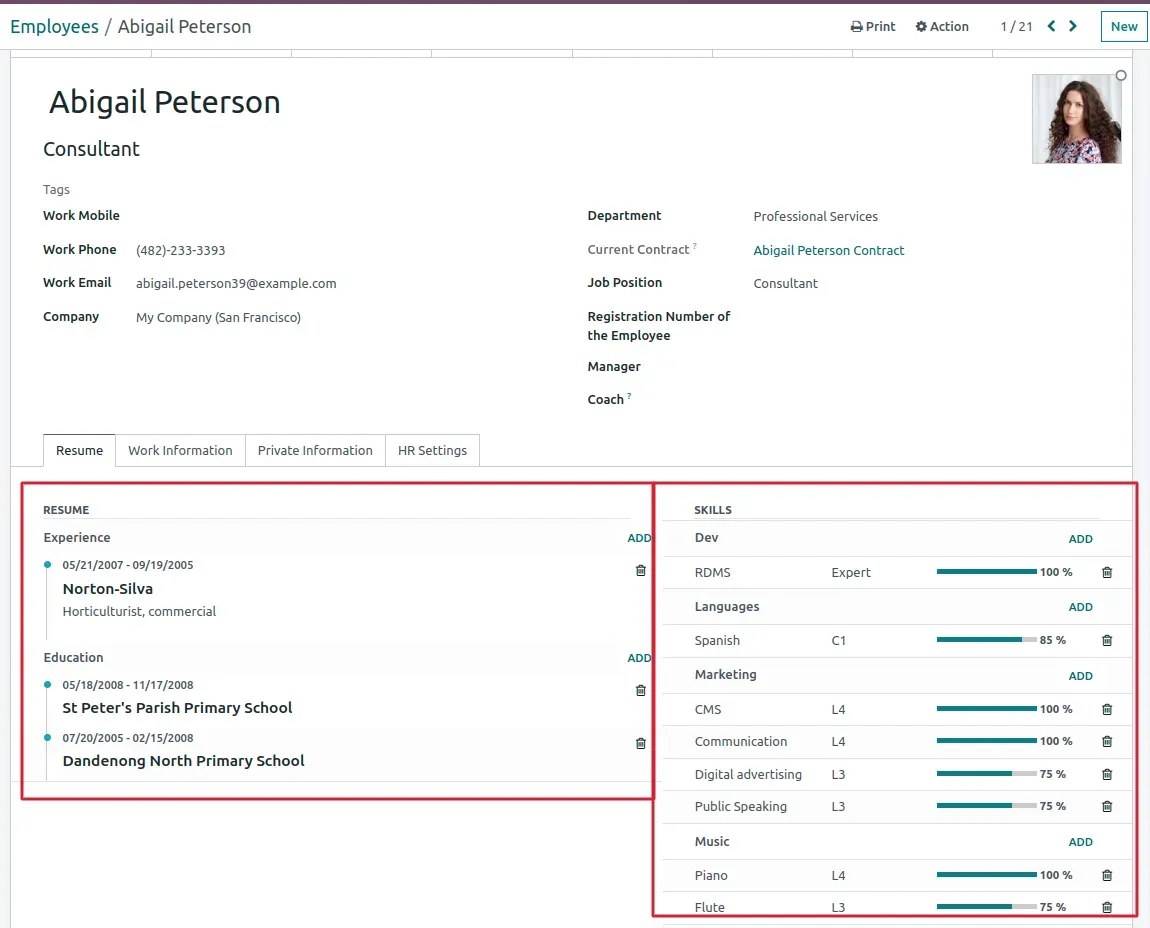

Unused Talent

Skill Management: Odoo's HR module helps you manage employee skills and competencies. As a result, you can ensure you're using talents effectively across different projects and tasks.

How to easily manage your Human Resources with Odoo 16?

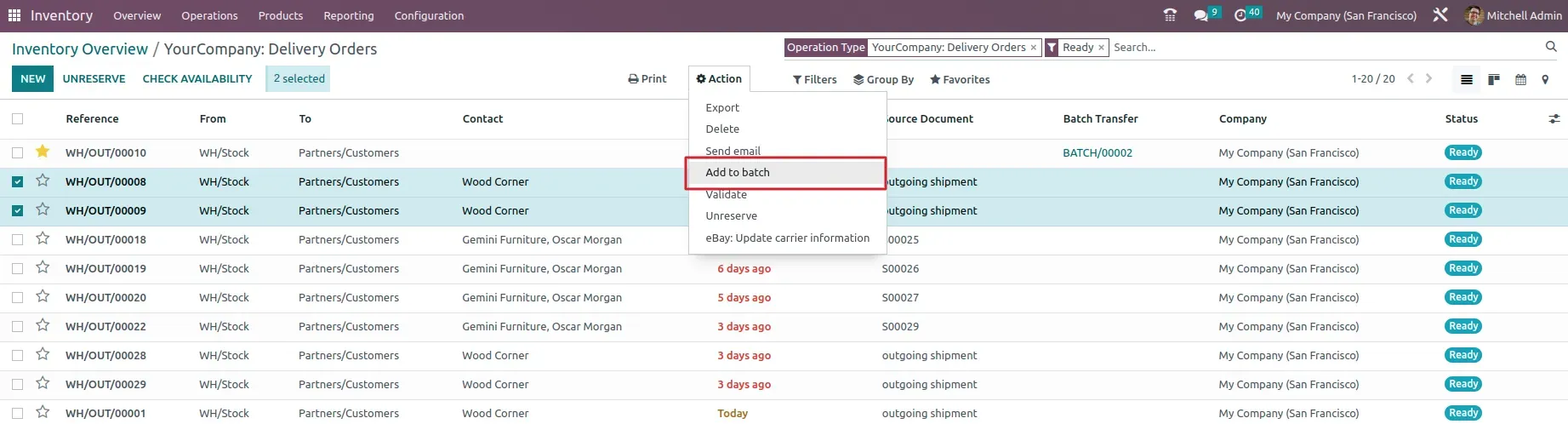

Transportation

Inventory Module: You can reduce transportation waste by combining multiple delivery orders into a single shipment using the Odoo batch picking feature.

Inventory

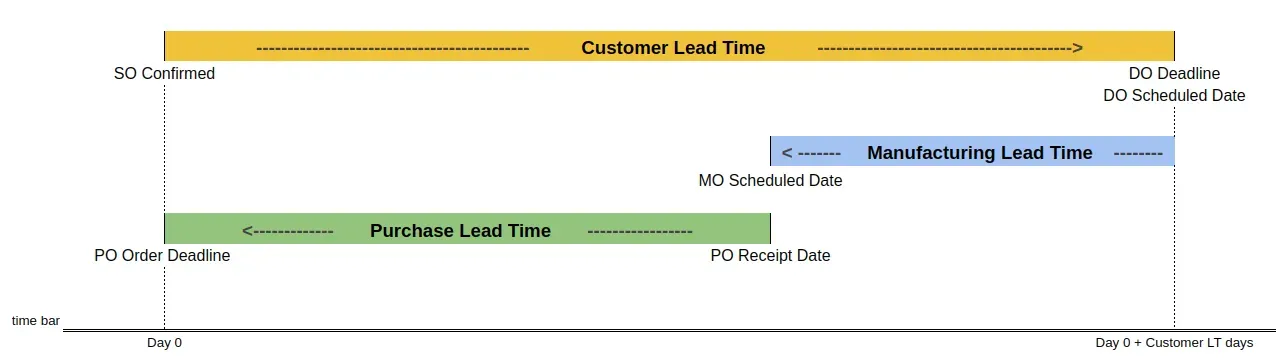

Just-in-Time Inventory: Odoo's inventory management features, including automated replenishment, support a just-in-time approach to inventory. You can therefore reduce excess stock and inventory waste.

How to set up lead times

Motion

Work Orders Management: While not directly managed by Odoo, you can use the system to monitor and optimize work processes. Such a feature reduces unnecessary motion through work instructions.

Extra Processing

Process Mapping: Odoo's workflow visualization features help map out processes and identify areas of unnecessary or redundant steps. This approach leads to streamlined processes and will reduce extra processing.

Conclusion

In conclusion, the combination of Odoo's flexible features and Lean manufacturing principles offers a promising path toward waste reduction and operational improvement. It is crucial to adopt a culture of continuous improvement, supported by organizational commitment and careful process analysis. When you effectively use the capabilities of Odoo within the framework of lean methodology, your business processes can reduce waste in a significant way. Lean's ability to reduce waste and Odoo's usefulness dynamically come together and work in harmony to pave the way for successful streamlining.

At ERPGAP we’ve assisted multiple companies to optimize their Lean Manufacturing results with Odoo. Do you need help to implement any of these features in your company? Don’t hesitate to contact us!