Using a subcontract manufacturing process in Odoo is a strategy for all sized companies. It is a way to:

- Prevent unnecessary risks

- Reduce operational costs

- Give the opportunity to have specialized work outside of company strengths

And those are only some of the reasons.

Odoo 13 created a very intuitive way of subcontracting for your company. It can save a lot of time for your supply chain manager and can be used by employees with different levels of expertise.

Learn More About Odoo 13 Features

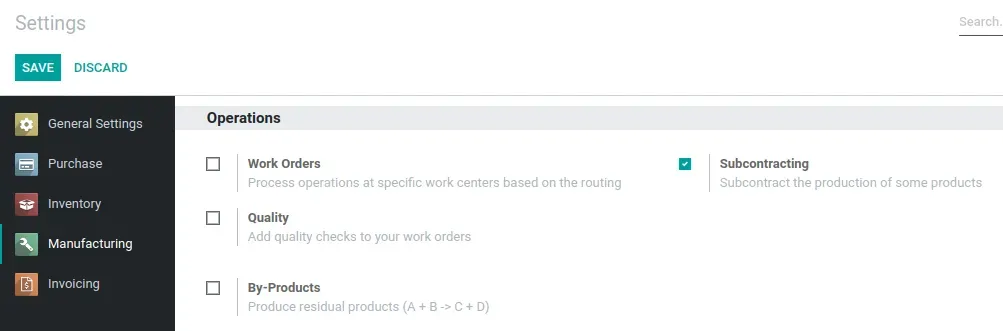

System Configuration

Configuration is the most important step in all processes to pay attention to. You can’t miss a thing or the final result will be difficult to achieve.

To start we need to install Purchase, Inventory and Manufacturing Apps.

![]()

After Apps are installed it’s time to allow Subcontracting on Manufacturing Settings and locations on Inventory settings. Then you can start to configure the products.

Odoo for Manufacturing & Inventory

Product Configuration

Setting up the products will influence the costs and Inventory workflow, so it is important at this time to think strategically. Do the counts and decide on the option that suits your company the best.

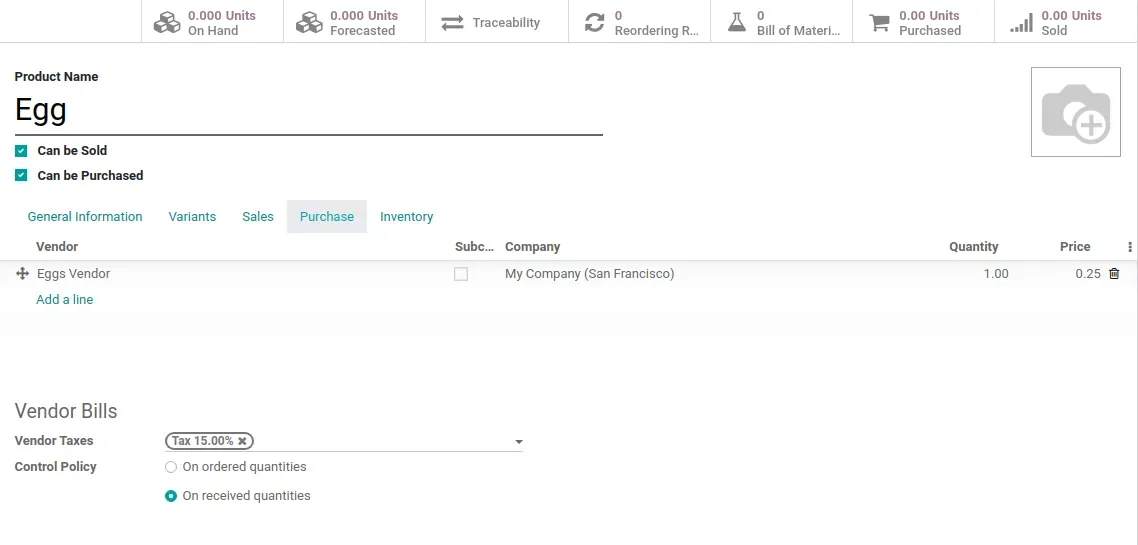

Raw Material

The example below is the raw material of my final product “Omelet”. This is an easy example to understand how subcontracting works as part of the manufacturing process in Odoo.

To start, make sure the Vendor, Vendor Price and Quantity are there as Sales Price and Cost on General Information.

Resupply Subcontractor

Choosing how to resupply subcontractors with raw materials will depend on the operational costs your company has. Which pays off more?

- Staying in your inventory and transporting only the essentials to satisfy each purchase

- Transporting large quantities to the subcontractor's warehouse.

There are three ways to resupply a subcontractor when working with this manufacturing process in Odoo:

- The first two we just need to check Buy on Routes.

- Create a delivery order to the subcontractor manually. Every time your subcontractor needs components you address a delivery order with the quantity you want to send.

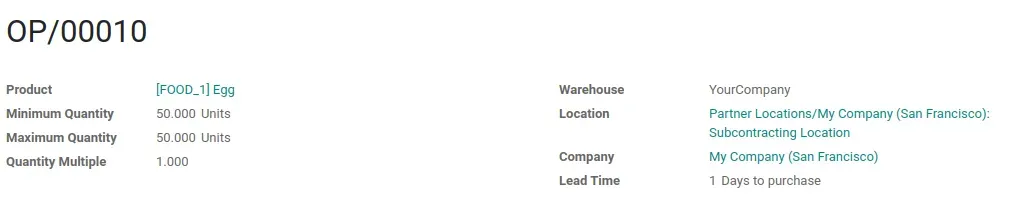

- Create a Reordering Rule to the Subcontractor. The subcontractor will never be short of eggs to produce omelets, because whenever the rule is initiated, a delivery order is generated automatically with the quantities you configure.

Inventory → Master Data → Reordering Rules → Create

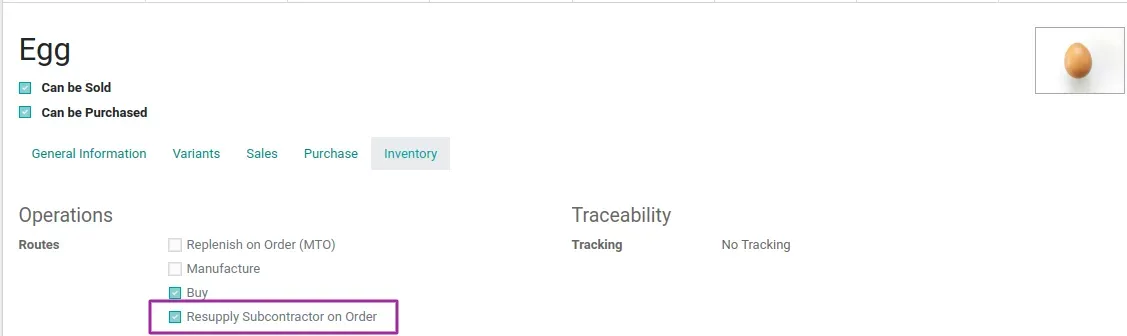

- Resupply subcontractor on Order. In this case you need to check the box below, and you will automatically send the same quantity you need to satisfy the purchase order to your subcontractor. Let’s use this configuration for the example below.

Final Product

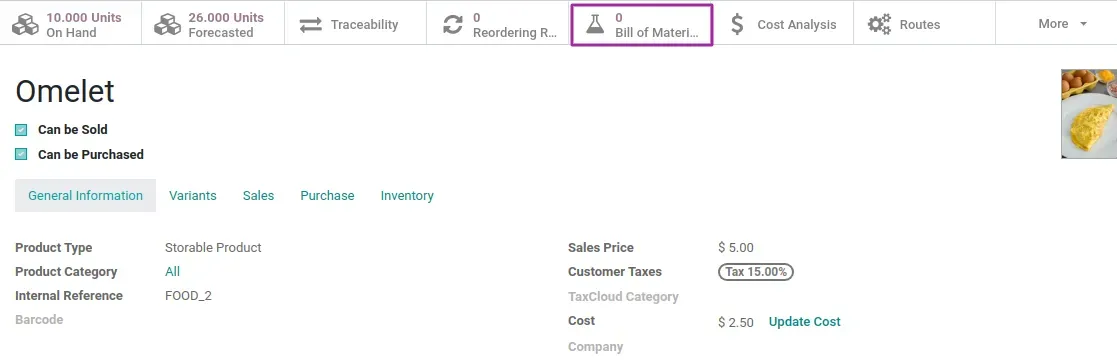

In Manufacturing in Odoo, the Final Product is the one you will subcontract, and to activate the subcontractor's feature, it’s necessary to create a Bill of Material. You can do it by clicking the Button below on the Product page.

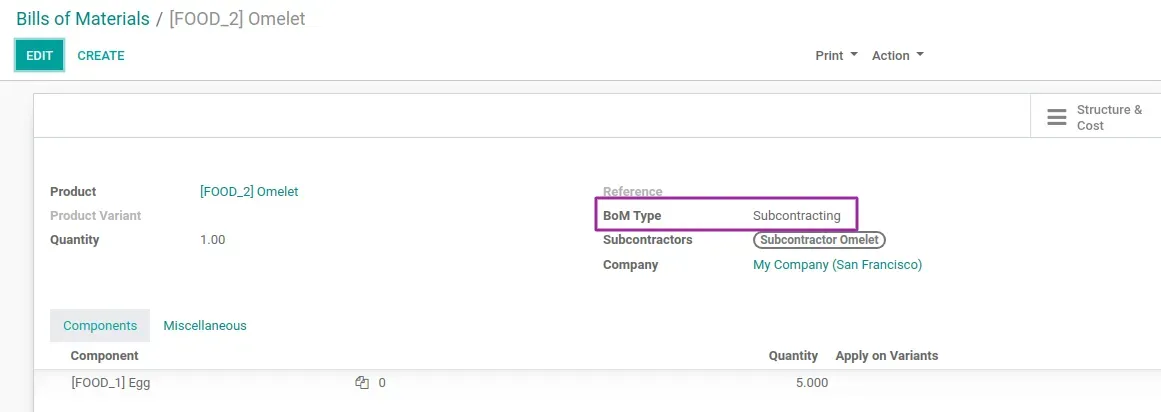

Make sure BoM Type is Subcontracting and that you set the right subcontractors. In this example Subcontractor will need 5 Eggs to produce the Omelet.

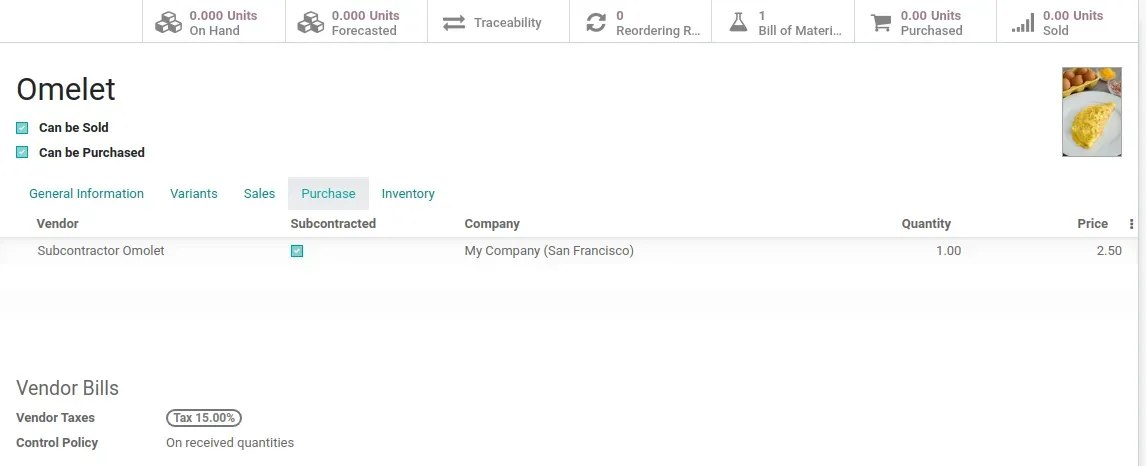

After the creation of BoM, Vendor is automatically checked as subcontracted:

Subcontractor Workflow

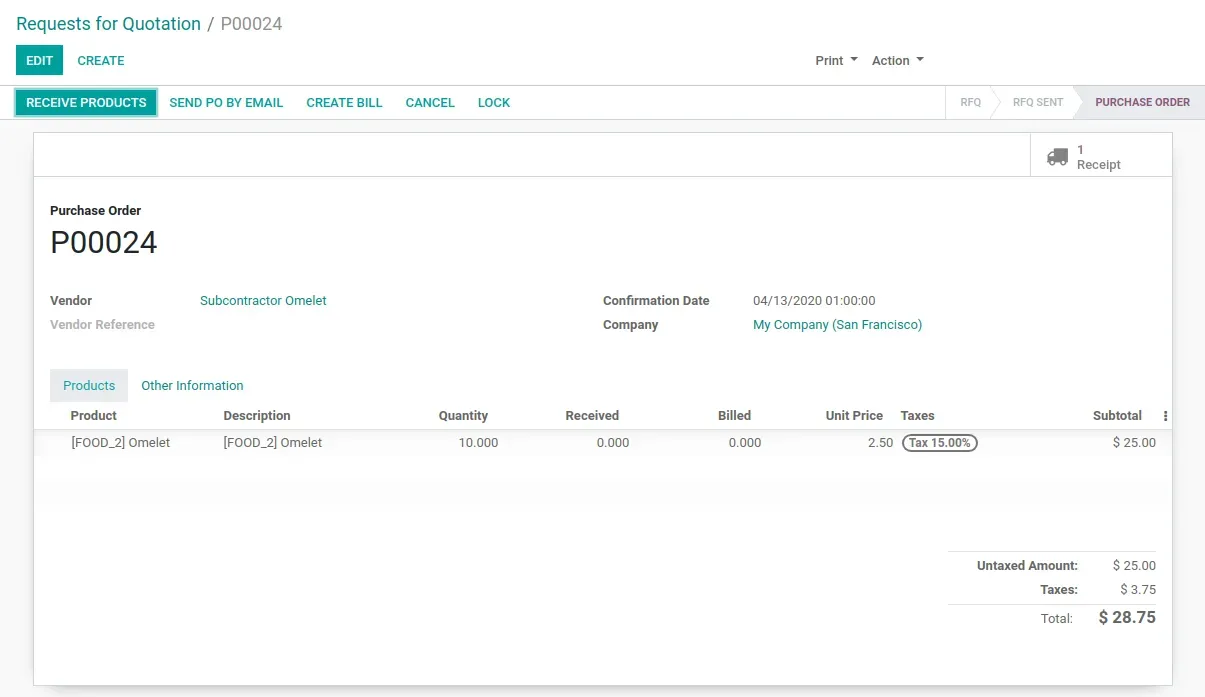

Firstly, you’ll create a Purchase Order with Subcontractor Omelet as the vendor and you choose Omelet as the product:

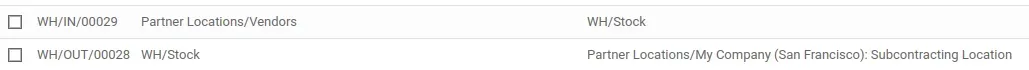

As mentioned before, for this example, we will Resupply Subcontractor on Order with Eggs. Because of that, two Inventory moves are created as soon as you confirm the Purchase Order.

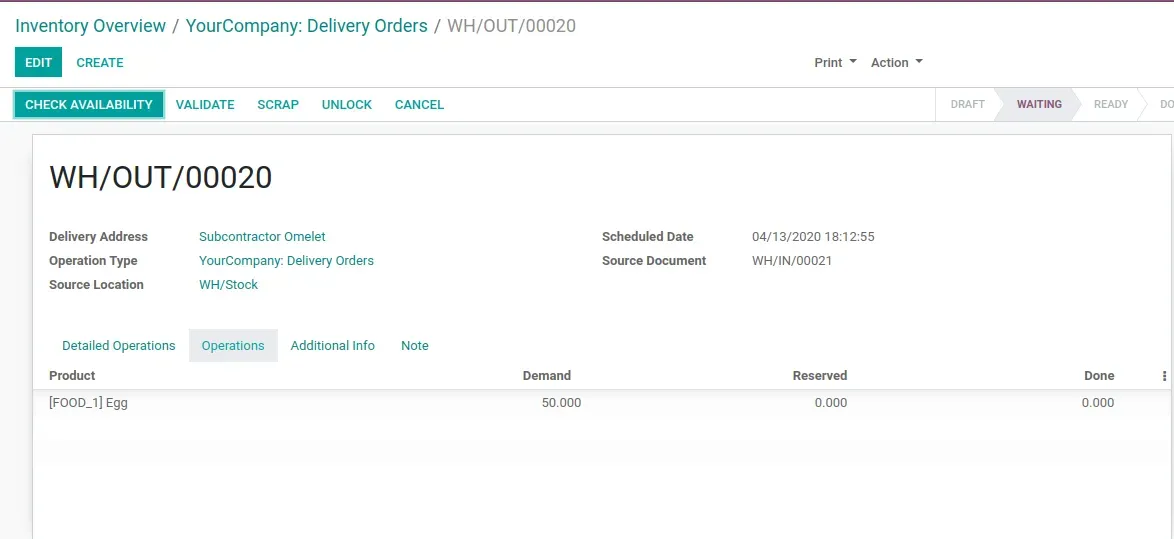

The first move to validate is the Delivery of the Eggs to the subcontractor's factory. Here you need to have the Eggs in your stock to move them to subcontractor Stock. Also in this step, you can add more or fewer Eggs to deliver to your subcontractor. That is important to know because you may need to refine the perfect recipe for your final product, or just because some subcontractor inventory has broken.

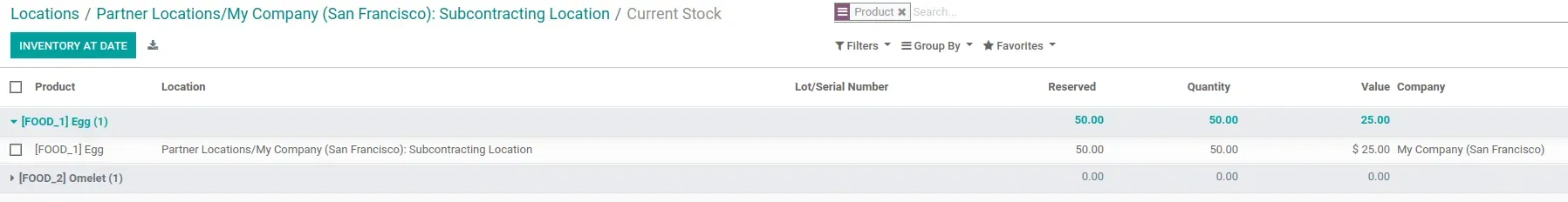

When the Delivery Order is validated you can see that eggs have been transferred to the Subcontractor’s location, where it is the perfect place to track the inventory you sent.

If you had chosen the other two options for resupplying, only one Inventory move would appear when confirming PO:

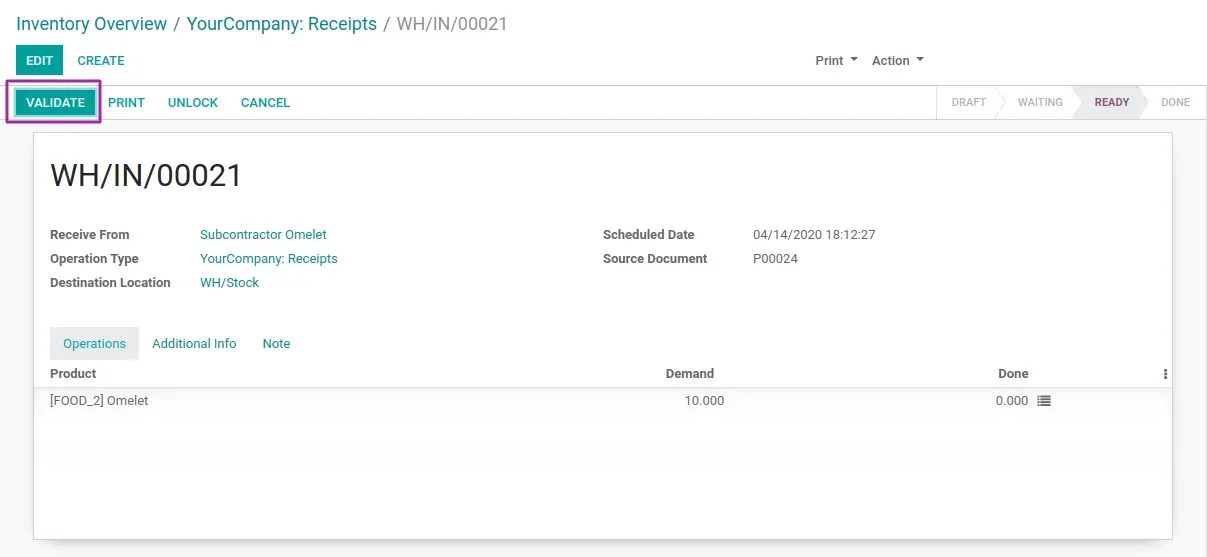

And that move is also the last step of this process.

This is the move from subcontractor to our warehouse, when we receipt the final Product, and we can find it in our stock location.

Sometimes manufacturing subcontracting opportunities will benefit your company substantially, so it is important to have ERP working perfectly and as automatically as possible. The standard module is a great foundation to get your company working smoothly. Here, the possibility to customize it is what will define it as being a good or great choice.

Let us help with your customization of Odoo manufacturing features, to enjoy the best results.