Do you run a business where the make-to-order (MTO) process is mandatory?

Do you manage many orders with small quantities every day instead of fewer orders with larger quantities? Are you having trouble using Odoo to organize your production orders?

We’ll help you find the perfect configuration for your work center to make planning a much easier and more intuitive process.

Learn About Our Support and Onboarding ServicesSetting Up Odoo Work Centers

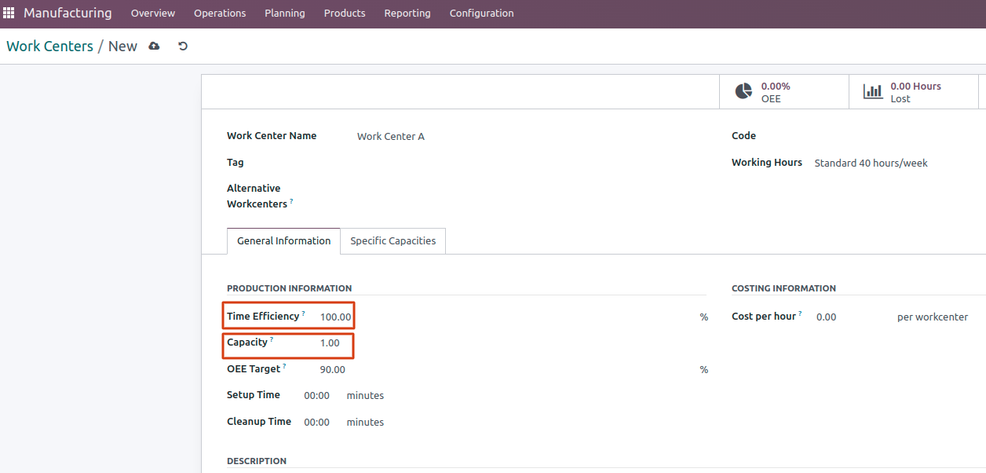

In Odoo, there are several parameters in the work center configuration that you need to set up to better reflect the reality of your shopfloor and plan accordingly. Among these, there are two very important ones, namely:

- Capacity: This is the number of units that can be produced in parallel (at the same time) in the same Manufacturing Order at a particular work center. The default setting is 1 unit.

- Time efficiency: You use this field to calculate the expected duration of a work order at the specific work center. The default is 100%, i.e. if an operation takes 60 minutes, it will actually take 60 minutes, neither more nor less.

In this way, it will be possible to include several scenarios that combine changes between these fields

As a result, we’ll have three different situations to handle:

- Change Work Center’s capacity

- Change Work Center’s capacity and time efficiency

- Change Work Center’s time efficiency

Case Study - 3 Work Center Scenarios

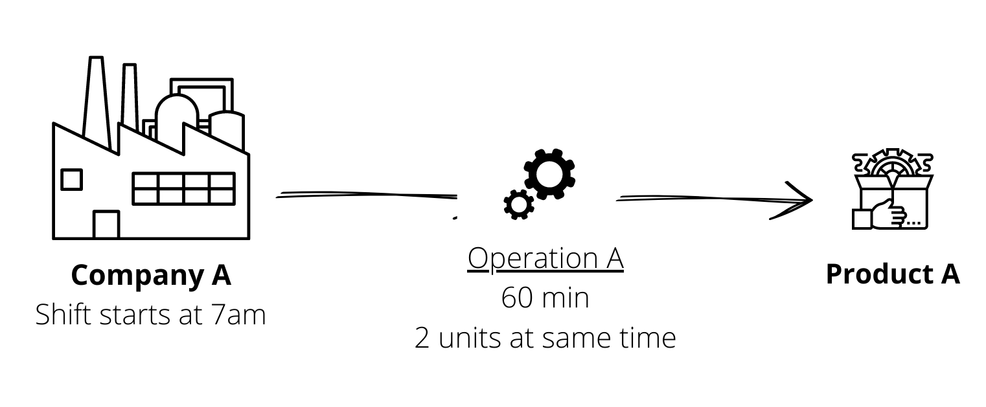

Let’s take Company A with the following characteristics to see how the various scenarios work:

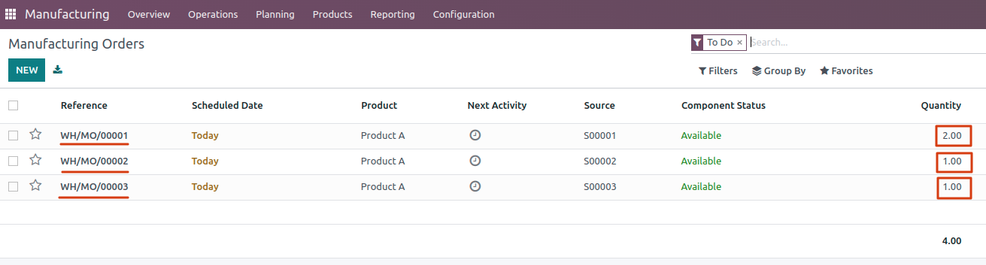

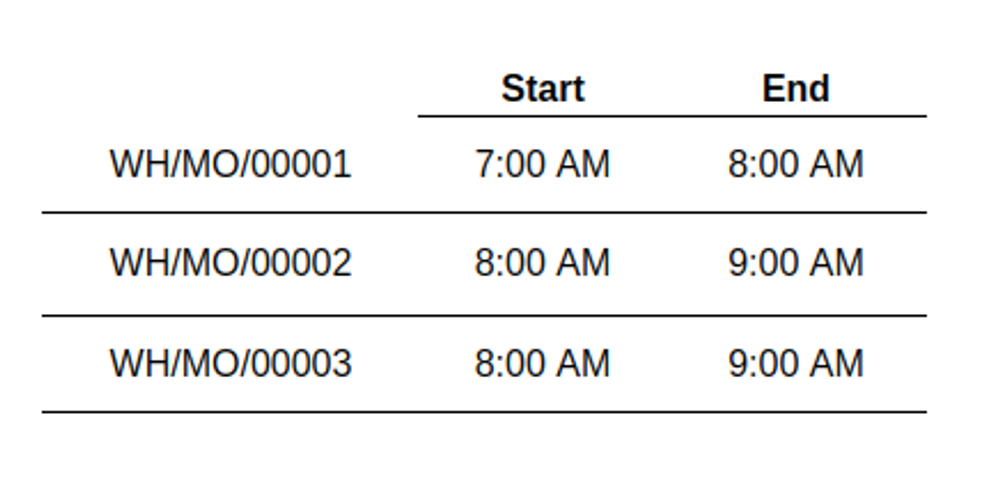

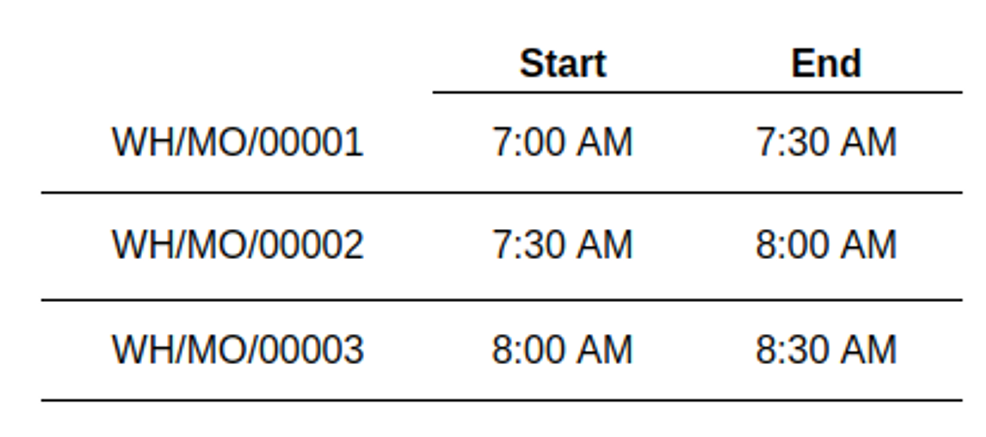

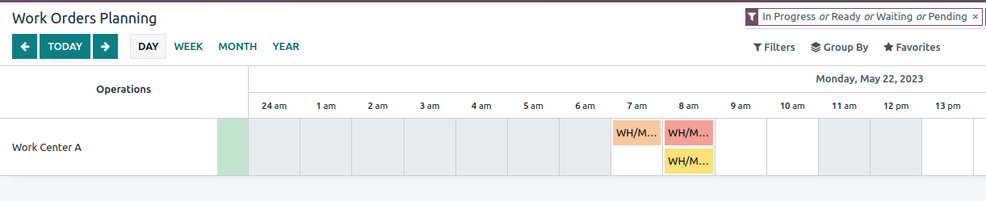

There are three manufacturing orders to be scheduled and we will plan all of them to start on the 22nd of May at 7 am:

- WH/MO/00001 with 2 units to produce

- WH/MO/00002 with 1 unit to produce

- WH/MO/00003 with 1 unit to produce

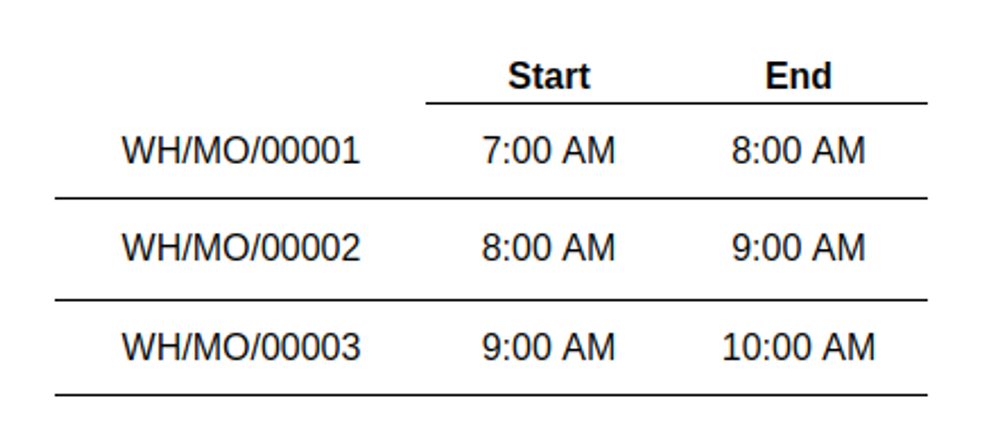

The expected time to complete the orders is 120 minutes. On the shopfloor the planned schedule will be:

Let’s have a look at how Odoo behaves in each scenario and see which one best matches the characteristics and needs of this business.

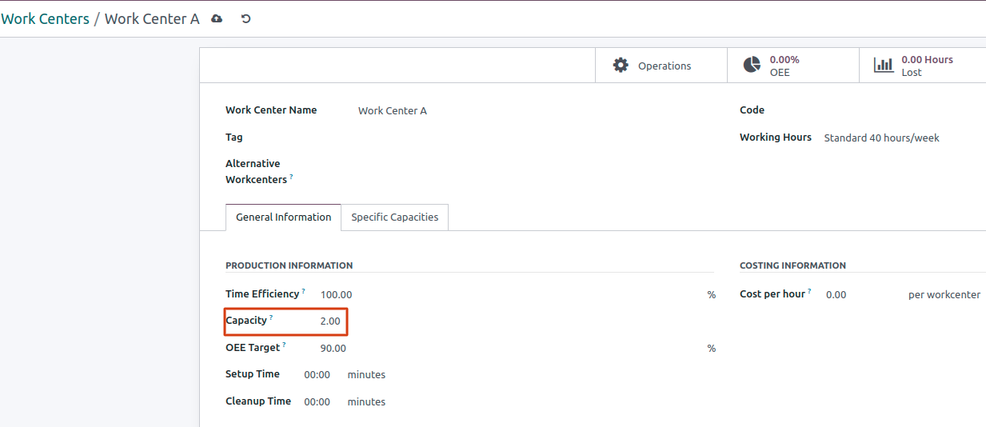

1. Change Work Center’s Capacity

Let’s change the capacity from 1 unit to 2 units once Work Center A can manufacture 2 units concurrently.

However, by definition, capacity is the number of items you are able to produce at the same time, from the same Manufacturing Order. Therefore, it will not be possible to plan WH/MO/00002 and WH/MO/00003 at the same time with this configuration. All of the orders will be completed in 180 minutes, which is an hour longer than on the shopfloor.

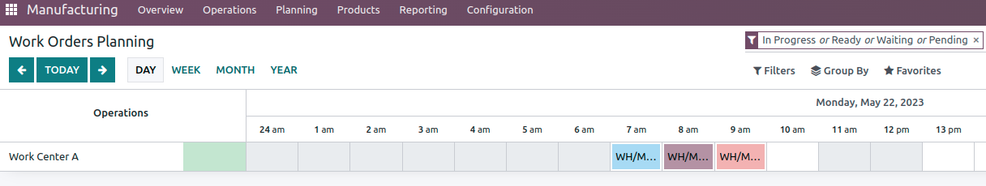

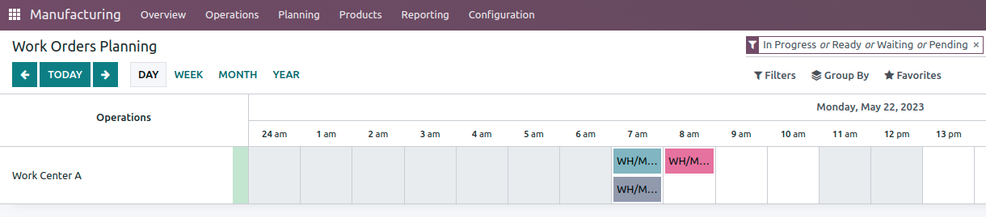

In Gantt view, the plan will look like this:

Summing up, this configuration will work if you have a single MO to produce 2 units of product A, as we have with WH/MO/00001. However, it won’t work if you have 2 units from different orders as is the case with WH/MO/00002 and WH/MO/00003.

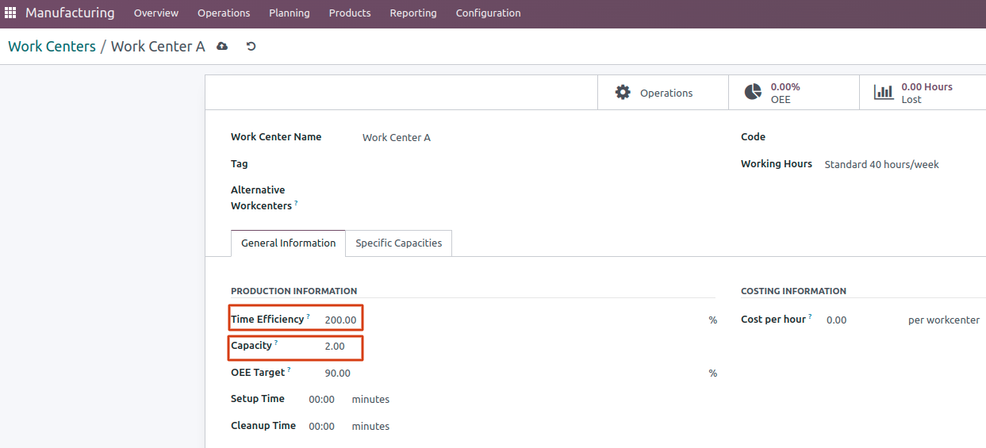

2. Changing the WC Capacity and Time Efficiency

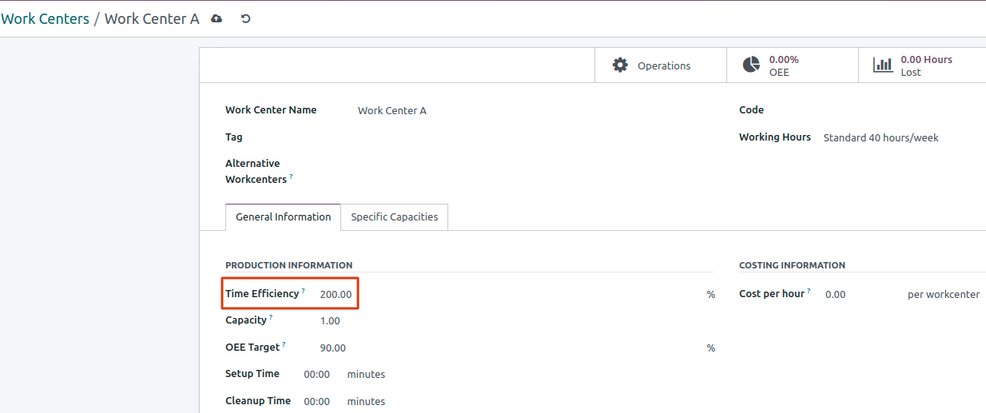

Let’s try to modify not only the capacity but also the time efficiency value.

So in 1 hour, we will be able to produce WH/MO/00002 and WH/MO/00003. Note that it won’t happen at the same time but you’re virtually reducing the production time of these orders. Operation A takes 60 minutes and with 200% time efficiency, it will take half the time, 30 minutes.

Nonetheless, it will not take into account the number of items you want to produce and will reduce all the operations, whether they have one or more units to produce.

With this configuration, the production of these orders starts at 7 am and ends at 8:30 am which is actually impossible due to resource constraints.

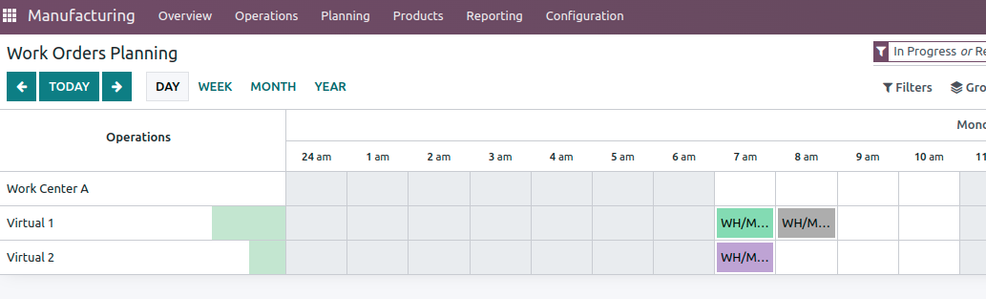

In Gantt view, the plan will look like this:

Consequently, this configuration will work if you have two Manufacturing Orders with one unit each, as is the case with both WH/MO/00002 and WH/MO/00003. However, it doesn’t work if you have one order with 2 units, as we have with WH/MO/00001.

Start You Project Now3. Changing the WC Time Efficiency

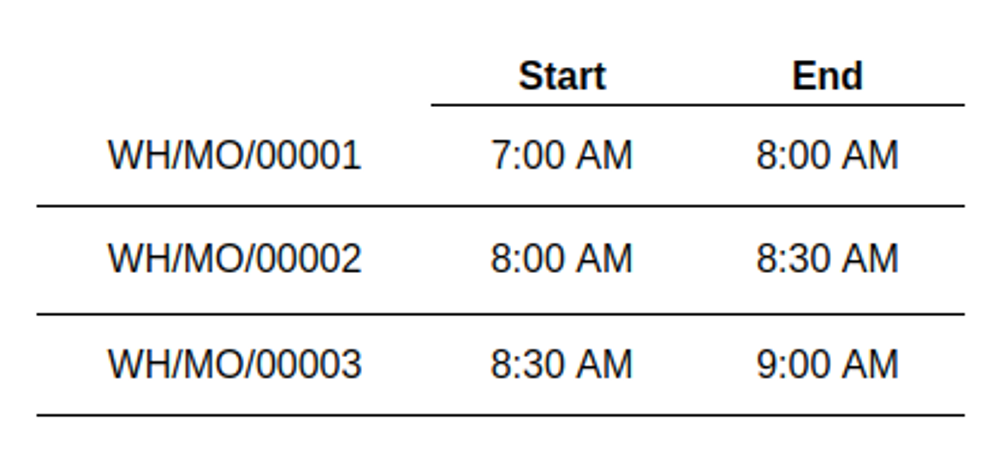

What if we just alter time efficiency while leaving capacity at its default setting? What will happen?

This configuration gives you the virtual scenario that’s closest to reality. It will take 120 minutes to produce all the orders, just like in real life. There is only a difference in the actual duration of orders WH/MO/00002 and WH/MO/00003, but the process finishes at the expected time.

In Gantt view, the plan will look like this:

Alternative Work Centers

A standout feature of Odoo is the many ways it allows you to customize setups, so it closely matches your shopfloor in reality. Using alternative work centers is one option to help you obtain an ideal setup.

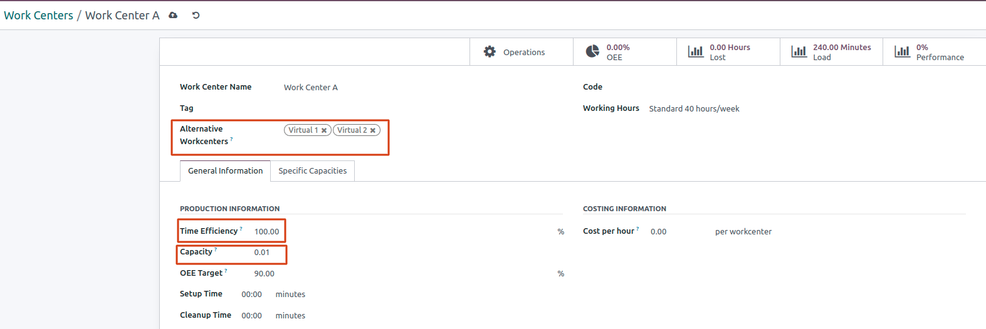

Let’s say Company A has two employees working in work center A and you want to distribute the orders between them and see this distribution in Gantt view.

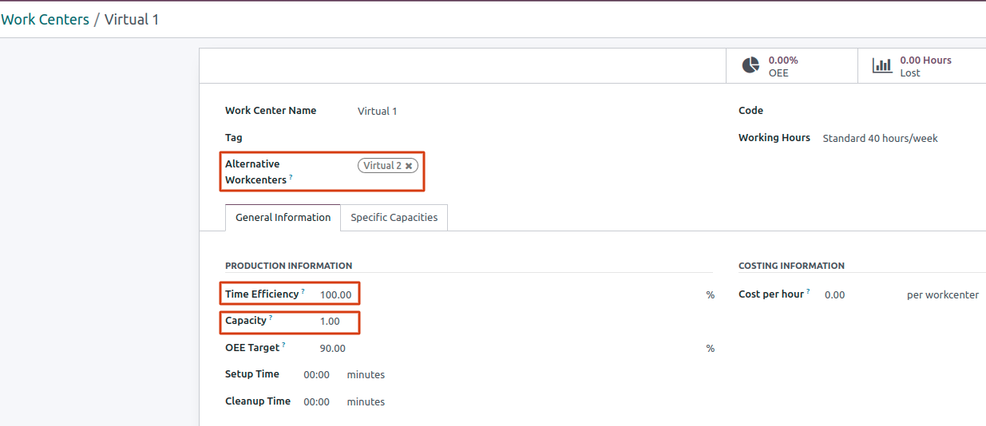

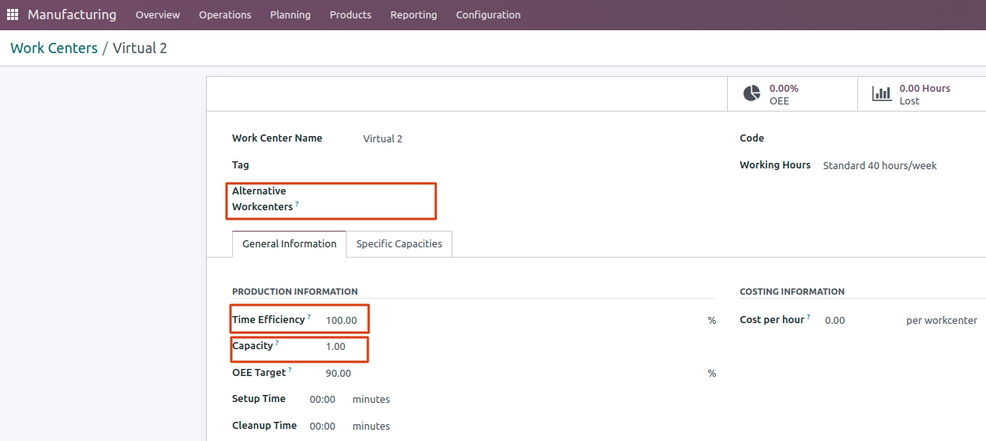

Making use of the functionality for alternative work centers is a simple method to accomplish that. To begin, you must create new virtual work centers with the following settings:

The Virtual1 Work Center will represent one employee.

“Virtual 2 Work Center” will represent the additional employee.

Then, you must set the capacity of the main work center to a very low value and choose the alternative work centers.

When it becomes necessary to schedule new orders, Odoo will:

- Check this main work center.

- If it is underutilized, it schedules work orders for the first alternate work center, in this case, ‘Virtual 1’.

- If ‘Virtual 1’ is at full capacity, it schedules work orders for the second alternative work center (in this case Virtual 2).

With this setup, you can immediately identify the tasks that each of your employees is in charge of, simply by looking at your Gantt chart.

Odoo Latest Releases

In Odoo 16.0 there is a new feature that allows you to merge manufacturing orders, for which our first scenario will work perfectly. However, by merging them, the relationship between the manufacturing orders and the corresponding sales orders is lost. And in some cases, this relationship is crucial for managing production, so what we showed in the previous case study can be a great workaround.

Discover more Odoo 16 FeaturesIn Conclusion

Above you saw a practical example of how Odoo’s features like Gantt charts and customizable fields can help you better organize and monitor processes on the shopfloor. There are multiple other Odoo features you may find beneficial too.

Why not talk to our team, so we can help you set up an efficient, customized system that suits your business needs.

Start You Project Now